Truncated Header Machine Teeth Suppliers – Bench and long-hole drilling T38 (1 1/2 “) – LYNE

Truncated Header Machine Teeth Suppliers – Bench and long-hole drilling T38 (1 1/2 “) – LYNE Detail:

Bench and long-hole drilling T38 (1 1/2 ”)

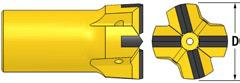

| Bits |

Diameter |

Buttons,mm |

Angle |

Flushing hole |

Weight approx kg |

Part No. |

||||||

|

mm |

in |

Front No Size |

Gauge No Size |

Type |

Front |

Gauge |

||||||

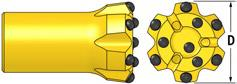

| Button bit | ||||||||||||

|

64 |

2 1/2” |

3×11 |

6×12 |

|

30º |

3 |

- |

1.6 |

1432-64T38-311/612-45-41 |

||

|

64 |

2 1/2” |

3×11 |

6×12 |

|

35º |

3 |

- |

1.6 |

1432-64T38-311/612-45-51 |

|||

|

64 |

2 1/2” |

5×9 |

8×10 |

|

35º |

4 |

- |

1.7 |

1432-64T38-59/810-45-51 |

||

|

70 |

2 3/4” |

5×10 |

8×11 |

|

30º |

4 |

- |

1.9 |

1432-70T38-510/811-45-41 |

|||

|

76 |

3” |

5×11 |

8×12 |

|

35º |

4 |

- |

2.3 |

1432-76T38-511/812-45-41 |

|||

|

76 |

3” |

5×11 |

8×11 |

|

40º |

4 |

- |

2.3 |

1432-76T38-511/811-45-51 |

|||

|

89 |

3 1/2” |

5×12 |

8×12 |

|

35º |

4 |

- |

3.2 |

1432-89T38-512/812-45-41 |

|||

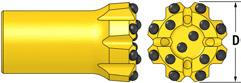

| Button bit, Flat face | ||||||||||

|

64 |

2 1/2” |

4×10 |

8×10 |

|

35º |

2 |

- |

1.6 |

1432-64T38-410/810-45-41 |

|

70 |

2 3/4” |

4×11 |

8×11 |

|

40º |

2 |

- |

1.9 |

1432-70T38-411/811-45-41 |

|

|

76 |

3” |

4×11 |

8×11 |

|

40º |

2 |

- |

2.3 |

1432-76T38-411/811-45-41 |

|

|

89 |

3 1/2” |

4×12 |

8×12 |

|

40º |

2 |

- |

2.3 |

1432-89T38-412/812-45-41 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

2 |

- |

2.3 |

1432-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

40º |

2 |

- |

2.3 |

1432-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

2 |

- |

3.2 |

1432-89T38-611/812-45-41 |

|

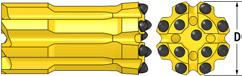

| Button bit, Drop center | ||||||||||

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

- |

1.6 |

1433-64T38-410/611-45-41 |

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

- |

1.6 |

1433-64T38-410/611-45-51 |

|

|

70 |

2 3/4” |

4×10 |

6×11 |

|

40º |

3 |

- |

1.9 |

1433-70T38-410/611-45-41 |

|

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

- |

2.3 |

1433-76T38-411/613-45-41 |

|

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

- |

2.3 |

1433-76T38-411/613-45-51 |

|

|

89 |

3 1/2” |

5×11 |

6×13 |

|

35º |

3 |

- |

3.2 |

1433-89T38-511/613-45-41 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

- |

2.3 |

1433-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

- |

2.3 |

1433-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

4 |

- |

3.2 |

1433-89T38-611/812-45-41 |

|

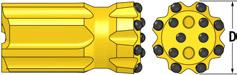

| Button bit, Retrac | ||||||||||

|

64 |

2 1/2” |

3×11 |

6×12 |

|

35º |

3 |

- |

2.2 |

1632-64T38-311/612-45-41 |

|

64 |

2 1/2” |

3×11 |

6×12 |

|

35º |

3 |

- |

2.2 |

1632-64T38-311/612-45-51 |

|

|

64 |

2 1/2” |

5×9 |

8×10 |

|

35º |

4 |

- |

2.2 |

1632-64T38-59/810-45-51 |

|

70 |

2 3/4” |

5×10 |

8×11 |

|

30º |

4 |

- |

2.4 |

1632-70T38-510/811-45-41 |

|

|

76 |

3” |

5×11 |

8×12 |

|

35º |

4 |

- |

2.9 |

1632-76T38-511/812-45-41 |

|

|

76 |

3” |

5×11 |

8×11 |

|

40º |

4 |

- |

2.9 |

1632-76T38-511/811-45-51 |

|

|

89 |

3 1/2” |

5×12 |

8×12 |

|

35º |

4 |

- |

3.2 |

1632-89T38-512/812-45-41 |

|

| Button bit, Retrac, Flat face | ||||||||||

|

64 |

2 1/2” |

4×10 |

8×10 |

|

35º |

2 |

- |

2.2 |

1531-64T38-410/810-45-41 |

|

64 |

2 1/2” |

4×10 |

8×10 |

|

35º |

2 |

- |

2.2 |

1531-64T38-410/810-45-51 |

|

|

70 |

2 3/4” |

4×11 |

8×11 |

|

40º |

2 |

- |

2.4 |

1531-70T38-411/811-45-41 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

2 |

- |

3.2 |

1531-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

40º |

2 |

- |

3.2 |

1531-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

2 |

- |

4.7 |

1531-89T38-611/812-45-41 |

|

| Button bit, Retrac, Drop center | ||||||||||

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

1 |

2.2 |

1533-64T38-410/611-45-41 |

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

1 |

2.2 |

1533-64T38-410/611-45-51 |

|

|

70 |

2 3/4” |

4×10 |

6×11 |

|

40º |

3 |

1 |

2.4 |

1533-70T38-410/611-45-41 |

|

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

1 |

3.2 |

1533-76T38-411/613-45-41 |

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

1 |

3.2 |

1533-76T38-411/613-45-51 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

1 |

3.2 |

1533-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

1 |

3.2 |

1533-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

4 |

1 |

4.7 |

1533-89T38-611/812-45-41 |

|

| X bit | ||||||||||

|

64 |

2 1/2” |

- |

- |

- |

- |

1 |

2 |

2.0 |

1321-64T38-25/13-42-23 |

|

76 |

3” |

- |

- |

- |

- |

1 |

2 |

2.6 |

1321-64T38-25/13-42-23 |

|

| Guide bit | ||||||||||

|

64 |

2 1/2” |

4×9 |

6×11 |

|

35º |

3 |

1 |

1.9 |

1632-64T38-49/611-45-51 |

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

- |

2.4 |

1632-76T38-610/811-45-51 |

|

| Reaming bit, T38 | ||||||||||

|

102 |

4” |

9×12 |

8×12 |

|

35º |

2 |

2 |

3.6 |

1441-102T38-912/812-45-41 |

|

127 |

5” |

9×13 |

8×13 |

|

35º |

2 |

2 |

6.9 |

1441-127T38-913/813-45-41 |

|

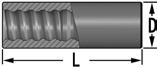

| Rods |

Length |

Diameter |

Weight approx kg |

Part No. |

||

|

mm |

ft/in |

mm |

inch |

|||

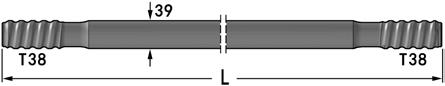

| Extension rod, T38-Round39-T38 | ||||||

|

1220 |

4' |

39 |

1 1/2” |

9.9 |

23R39-T38-1220-23 |

|

1525 |

5' |

39 |

1 1/2” |

12.4 |

23R39-T38-1525-23 |

|

|

1830 |

6' |

39 |

1 1/2” |

14.9 |

23R39-T38-1830-23 |

|

|

3050 |

10' |

39 |

1 1/2” |

24.7 |

23R39-T38-3050-23 |

|

|

3660 |

12' |

39 |

1 1/2” |

29.7 |

23R39-T38-3660-23 |

|

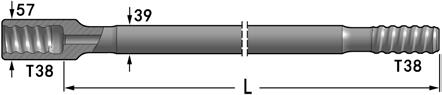

| MF-rod, T38-Round39-T38 | ||||||

|

1220 |

4' |

39 |

1 1/2” |

11.5 |

24R39-T38/57-1220-23 |

|

1525 |

5' |

39 |

1 1/2” |

14.4 |

24R39-T38/57-1525-23 |

|

|

1830 |

6' |

39 |

1 1/2” |

16.5 |

24R39-T38/57-1830-23 |

|

|

3050 |

10' |

39 |

1 1/2” |

26.4 |

24R39-T38/57-3050-23 |

|

|

3660 |

12' |

39 |

1 1/2” |

31.3 |

24R39-T38/57-3660-23 |

|

|

4270 |

14' |

39 |

1 1/2” |

36.2 |

24R39-T38/57-4270-23 |

|

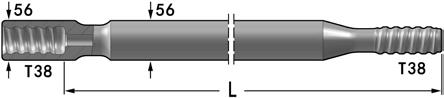

| Guide tube | ||||||

|

1830 |

6' |

56 |

1 13/64” |

18.4 |

24G56-T38/56-1830-23 |

|

3660 |

12' |

56 |

1 13/64” |

33.8 |

24G56-T38/56-3660-23 |

|

| Coupling sleeve | |||||||

|

T38 |

190 |

6 1/8” |

55 |

1 5/32” |

2.0 |

31-T38-55-190-23 |

Description: extension rod, other names are Extension drill steel, Extension drill rod, and Extension steel, M/F rod ( Speedrod ) , Produce Hexagonal and round cross sections, Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods are generally lighter thanhexagonal rods and are normally used in extension drilling applications. With the longer steel tending to be larger in diameter, conventional extension steel is characterized by a duplicate thread on each end of the steel.

Main button bits is:

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Truncated Header Machine Teeth Suppliers – Bench and long-hole drilling T38 (1 1/2 “) – LYNE , The product will supply to all over the world, such as: Hanover, Finland, Leicester, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!