Truncated Header Machine Teeth Supplier – Bench and long-hole drilling T38 (1 1/2 “) – LYNE

Truncated Header Machine Teeth Supplier – Bench and long-hole drilling T38 (1 1/2 “) – LYNE Detail:

Bench and long-hole drilling T38 (1 1/2 ”)

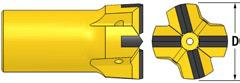

| Bits |

Diameter |

Buttons,mm |

Angle |

Flushing hole |

Weight approx kg |

Part No. |

||||||

|

mm |

in |

Front No Size |

Gauge No Size |

Type |

Front |

Gauge |

||||||

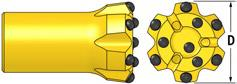

| Button bit | ||||||||||||

|

64 |

2 1/2” |

3×11 |

6×12 |

|

30º |

3 |

- |

1.6 |

1432-64T38-311/612-45-41 |

||

|

64 |

2 1/2” |

3×11 |

6×12 |

|

35º |

3 |

- |

1.6 |

1432-64T38-311/612-45-51 |

|||

|

64 |

2 1/2” |

5×9 |

8×10 |

|

35º |

4 |

- |

1.7 |

1432-64T38-59/810-45-51 |

||

|

70 |

2 3/4” |

5×10 |

8×11 |

|

30º |

4 |

- |

1.9 |

1432-70T38-510/811-45-41 |

|||

|

76 |

3” |

5×11 |

8×12 |

|

35º |

4 |

- |

2.3 |

1432-76T38-511/812-45-41 |

|||

|

76 |

3” |

5×11 |

8×11 |

|

40º |

4 |

- |

2.3 |

1432-76T38-511/811-45-51 |

|||

|

89 |

3 1/2” |

5×12 |

8×12 |

|

35º |

4 |

- |

3.2 |

1432-89T38-512/812-45-41 |

|||

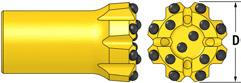

| Button bit, Flat face | ||||||||||

|

64 |

2 1/2” |

4×10 |

8×10 |

|

35º |

2 |

- |

1.6 |

1432-64T38-410/810-45-41 |

|

70 |

2 3/4” |

4×11 |

8×11 |

|

40º |

2 |

- |

1.9 |

1432-70T38-411/811-45-41 |

|

|

76 |

3” |

4×11 |

8×11 |

|

40º |

2 |

- |

2.3 |

1432-76T38-411/811-45-41 |

|

|

89 |

3 1/2” |

4×12 |

8×12 |

|

40º |

2 |

- |

2.3 |

1432-89T38-412/812-45-41 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

2 |

- |

2.3 |

1432-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

40º |

2 |

- |

2.3 |

1432-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

2 |

- |

3.2 |

1432-89T38-611/812-45-41 |

|

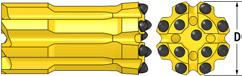

| Button bit, Drop center | ||||||||||

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

- |

1.6 |

1433-64T38-410/611-45-41 |

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

- |

1.6 |

1433-64T38-410/611-45-51 |

|

|

70 |

2 3/4” |

4×10 |

6×11 |

|

40º |

3 |

- |

1.9 |

1433-70T38-410/611-45-41 |

|

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

- |

2.3 |

1433-76T38-411/613-45-41 |

|

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

- |

2.3 |

1433-76T38-411/613-45-51 |

|

|

89 |

3 1/2” |

5×11 |

6×13 |

|

35º |

3 |

- |

3.2 |

1433-89T38-511/613-45-41 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

- |

2.3 |

1433-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

- |

2.3 |

1433-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

4 |

- |

3.2 |

1433-89T38-611/812-45-41 |

|

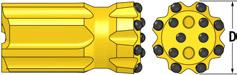

| Button bit, Retrac | ||||||||||

|

64 |

2 1/2” |

3×11 |

6×12 |

|

35º |

3 |

- |

2.2 |

1632-64T38-311/612-45-41 |

|

64 |

2 1/2” |

3×11 |

6×12 |

|

35º |

3 |

- |

2.2 |

1632-64T38-311/612-45-51 |

|

|

64 |

2 1/2” |

5×9 |

8×10 |

|

35º |

4 |

- |

2.2 |

1632-64T38-59/810-45-51 |

|

70 |

2 3/4” |

5×10 |

8×11 |

|

30º |

4 |

- |

2.4 |

1632-70T38-510/811-45-41 |

|

|

76 |

3” |

5×11 |

8×12 |

|

35º |

4 |

- |

2.9 |

1632-76T38-511/812-45-41 |

|

|

76 |

3” |

5×11 |

8×11 |

|

40º |

4 |

- |

2.9 |

1632-76T38-511/811-45-51 |

|

|

89 |

3 1/2” |

5×12 |

8×12 |

|

35º |

4 |

- |

3.2 |

1632-89T38-512/812-45-41 |

|

| Button bit, Retrac, Flat face | ||||||||||

|

64 |

2 1/2” |

4×10 |

8×10 |

|

35º |

2 |

- |

2.2 |

1531-64T38-410/810-45-41 |

|

64 |

2 1/2” |

4×10 |

8×10 |

|

35º |

2 |

- |

2.2 |

1531-64T38-410/810-45-51 |

|

|

70 |

2 3/4” |

4×11 |

8×11 |

|

40º |

2 |

- |

2.4 |

1531-70T38-411/811-45-41 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

2 |

- |

3.2 |

1531-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

40º |

2 |

- |

3.2 |

1531-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

2 |

- |

4.7 |

1531-89T38-611/812-45-41 |

|

| Button bit, Retrac, Drop center | ||||||||||

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

1 |

2.2 |

1533-64T38-410/611-45-41 |

|

64 |

2 1/2” |

4×10 |

6×11 |

|

35º |

3 |

1 |

2.2 |

1533-64T38-410/611-45-51 |

|

|

70 |

2 3/4” |

4×10 |

6×11 |

|

40º |

3 |

1 |

2.4 |

1533-70T38-410/611-45-41 |

|

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

1 |

3.2 |

1533-76T38-411/613-45-41 |

|

76 |

3” |

4×11 |

6×13 |

|

35º |

3 |

1 |

3.2 |

1533-76T38-411/613-45-51 |

|

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

1 |

3.2 |

1533-76T38-610/811-45-41 |

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

1 |

3.2 |

1533-76T38-610/811-45-51 |

|

|

89 |

3 1/2” |

6×11 |

8×12 |

|

35º |

4 |

1 |

4.7 |

1533-89T38-611/812-45-41 |

|

| X bit | ||||||||||

|

64 |

2 1/2” |

- |

- |

- |

- |

1 |

2 |

2.0 |

1321-64T38-25/13-42-23 |

|

76 |

3” |

- |

- |

- |

- |

1 |

2 |

2.6 |

1321-64T38-25/13-42-23 |

|

| Guide bit | ||||||||||

|

64 |

2 1/2” |

4×9 |

6×11 |

|

35º |

3 |

1 |

1.9 |

1632-64T38-49/611-45-51 |

|

76 |

3” |

6×10 |

8×11 |

|

35º |

4 |

- |

2.4 |

1632-76T38-610/811-45-51 |

|

| Reaming bit, T38 | ||||||||||

|

102 |

4” |

9×12 |

8×12 |

|

35º |

2 |

2 |

3.6 |

1441-102T38-912/812-45-41 |

|

127 |

5” |

9×13 |

8×13 |

|

35º |

2 |

2 |

6.9 |

1441-127T38-913/813-45-41 |

|

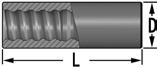

| Rods |

Length |

Diameter |

Weight approx kg |

Part No. |

||

|

mm |

ft/in |

mm |

inch |

|||

| Extension rod, T38-Round39-T38 | ||||||

|

1220 |

4' |

39 |

1 1/2” |

9.9 |

23R39-T38-1220-23 |

|

1525 |

5' |

39 |

1 1/2” |

12.4 |

23R39-T38-1525-23 |

|

|

1830 |

6' |

39 |

1 1/2” |

14.9 |

23R39-T38-1830-23 |

|

|

3050 |

10' |

39 |

1 1/2” |

24.7 |

23R39-T38-3050-23 |

|

|

3660 |

12' |

39 |

1 1/2” |

29.7 |

23R39-T38-3660-23 |

|

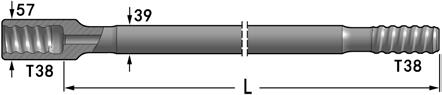

| MF-rod, T38-Round39-T38 | ||||||

|

1220 |

4' |

39 |

1 1/2” |

11.5 |

24R39-T38/57-1220-23 |

|

1525 |

5' |

39 |

1 1/2” |

14.4 |

24R39-T38/57-1525-23 |

|

|

1830 |

6' |

39 |

1 1/2” |

16.5 |

24R39-T38/57-1830-23 |

|

|

3050 |

10' |

39 |

1 1/2” |

26.4 |

24R39-T38/57-3050-23 |

|

|

3660 |

12' |

39 |

1 1/2” |

31.3 |

24R39-T38/57-3660-23 |

|

|

4270 |

14' |

39 |

1 1/2” |

36.2 |

24R39-T38/57-4270-23 |

|

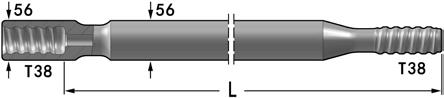

| Guide tube | ||||||

|

1830 |

6' |

56 |

1 13/64” |

18.4 |

24G56-T38/56-1830-23 |

|

3660 |

12' |

56 |

1 13/64” |

33.8 |

24G56-T38/56-3660-23 |

|

| Coupling sleeve | |||||||

|

T38 |

190 |

6 1/8” |

55 |

1 5/32” |

2.0 |

31-T38-55-190-23 |

Description: extension rod, other names are Extension drill steel, Extension drill rod, and Extension steel, M/F rod ( Speedrod ) , Produce Hexagonal and round cross sections, Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods are generally lighter thanhexagonal rods and are normally used in extension drilling applications. With the longer steel tending to be larger in diameter, conventional extension steel is characterized by a duplicate thread on each end of the steel.

Main button bits is:

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.

Product detail pictures:

Related Product Guide:

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for Truncated Header Machine Teeth Supplier – Bench and long-hole drilling T38 (1 1/2 “) – LYNE , The product will supply to all over the world, such as: Munich, Tunisia, Algeria, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!