Tapered tools, 11° taper

Tapered tools, 11° taper

| Bits |

Diameter |

Buttons,mm |

Angle |

Flushing hole |

Weight approx kg |

Part No. |

||||||

|

mm |

in |

Front No Size |

Gauge No Size |

Type |

Front |

Gauge |

||||||

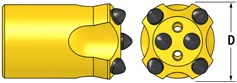

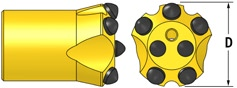

| Button bit—Short skirt. | ||||||||||||

|

32 |

1 1/4” |

2×7 |

3×8 |

|

35º |

1 |

2 |

0.24 |

1431-321122-27/38-45-51 |

||

|

34 |

1 11/32” |

1×8 |

3×8 |

|

35º |

1 |

1 |

0.26 |

1431-341122-18/38-45-51 |

|||

|

36 |

1 7/16” |

1×8 |

3×9 |

|

40º |

1 |

1 |

0.29 |

1431-361122-18/39-45-51 |

|||

|

38 |

1 1/2” |

2×8 |

3×9 |

|

40º |

1 |

1 |

0.32 |

1431-381122-28/39-45-51 |

|||

|

40 |

1 37/64” |

2×8 |

3×9 |

|

40º |

1 |

1 |

0.36 |

1431-401122-28/39-45-51 |

|||

| Button bit—Short skirt. | ||||||||||||

|

32 |

1 1/4” |

2×7 |

4×7 |

|

35º |

1 |

1 |

0.24 |

1431-321122-27/47-45-51 |

||

|

34 |

1 11/32” |

2×7 |

4×7 |

|

35º |

2 |

1 |

0.29 |

1431-341122-27/47-45-51 |

|||

|

36 |

1 7/16” |

2×7 |

4×8 |

|

35º |

2 |

1 |

0.32 |

1431-361122-27/48-45-51 |

|||

| Button bit—Short skirt. | ||||||||||||

|

32 |

1 1/4” |

2×7 |

5×7 |

|

40º |

1 |

1 |

0.24 |

1431-321122-27/57-45-51 |

||

|

34 |

1 11/32” |

2×7 |

5×7 |

|

35º |

1 |

1 |

0.29 |

1431-341122-27/57-45-51 |

|||

|

36 |

1 7/16” |

2×7 |

5×8 |

|

35º |

1 |

1 |

0.32 |

1431-361122-27/58-45-51 |

|||

|

38 |

1 1/2” |

2×7 |

5×8 |

|

35º |

1 |

1 |

0.34 |

1431-381123-27/58-45-51 |

|||

|

38 |

1 1/2” |

2×7 |

5×9 |

|

40º |

1 |

1 |

0.34 |

1431-381123-27/59-45-51 |

|||

|

40 |

1 37/64” |

2×7 |

5×9 |

|

35º |

1 |

1 |

0.39 |

1431-401123-27/59-45-51 |

|||

|

41 |

1 5/8” |

2×8 |

5×9 |

|

35º |

1 |

1 |

0.39 |

1431-411123-28/59-45-51 |

|||

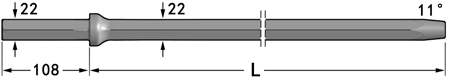

| Rods |

Lengte |

Weight approx kg |

Part No. |

|

|

mm |

Ft/in |

|||

| Shank 22×108mm(7/8”×4 1/4”) | ||||

|

610 |

2' |

2.20 |

21H22–11/108-0610-40 |

|

800 |

3'3″ |

2.78 |

21H22–11/108-0800-40 |

|

|

1220 |

4' |

4.06 |

21H22–11/108-1220-40 |

|

|

1830 |

6' |

5.92 |

21H22–11/108-1830-40 |

|

|

2000 |

6'7″ |

6.44 |

21H22–11/108-2000-40 |

|

|

2435 |

8' |

7.76 |

21H22–11/108-2435-40 |

|

|

3050 |

10' |

9.64 |

21H22–11/108-3050-40 |

|

|

3660 |

12' |

11.50 |

21H22–11/108-3660-40 |

|

|

4000 |

13'1″ |

12.54 |

21H22–11/108-4000-40 |

|

|

4800 |

15'9″ |

14.98 |

21H22–11/108-4800-40 |

|

|

5600 |

18'4″ |

17.42 |

21H22–11/108-5600-40 |

|

|

6400 |

21' |

19.86 |

21H22–11/108-6400-40 |

|

|

7200 |

23'6″ |

22.30 |

21H22–11/108-7200-40 |

|

|

8000 |

26'2″ |

24.74 |

21H22–11/108-8000-40 |

|

Main button bits is:

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.

Male / Male rod, Male/Female (M/F) Rod -Speed rod

M/F drill steel is an alternative to couplings sleeves to include the female part of the threaded connection as an integral part of the drill steel. M/F drill steel provides more rigid connections and is easier to uncouple

and handle. The service life also tends to be better than with separate couplings.

For Extension Rod and M/F steel process, the below two different types of heat treatment are used tostrengthen high speed and powerful percussive drill string components to maximize their performance and reliability.