-

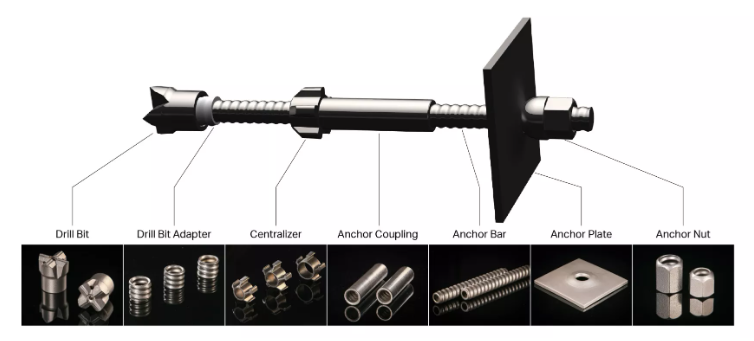

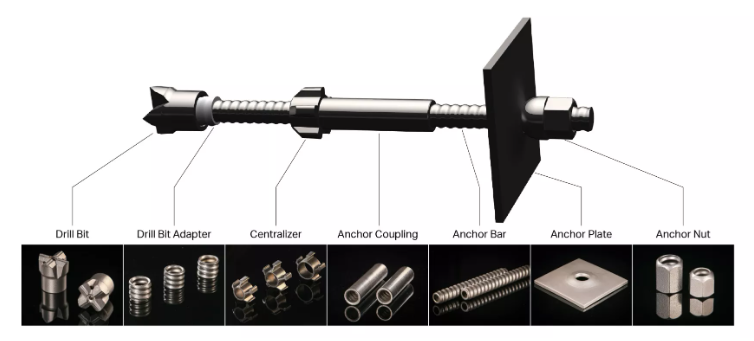

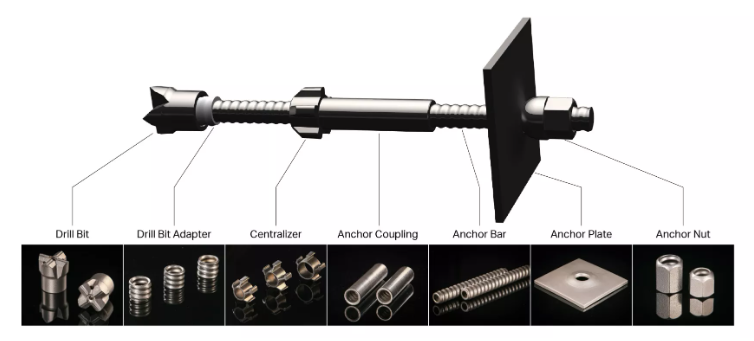

Hollow grouted rock bolt self drilling anchor bolt fixed rock self drilling anchor bar for Buildings

The Self Drilling Anchor system is comprised of a hollow threaded anchor bar with a sacrificial drill bit that performs drilling, anchoring and grouting in a single operation. Self drilling anchor system is mainly used in slope stabilization, tunneling pre-support, foundations with micro piles etc projects.

Advantages and Characteristics as below:

1. No casings required, because anchor bars can be drilled into loose soils without needing casings to support the boreholes.

2. Fast drilling and installation, because drilling, installation and grouting are in a single operation.

3. Both rope threads and trapezoid threads are robust and ideal for rotary-percussive drilling and ensuring a high level of bond with the borehole gout.

4. The hollow core not only serves for flushing during drilling, but also for grouting after drilling.

5. Continuous threads ensure the bars can be cut and coupled at any point, or extended.

6. Different anchor bits are available for different ground conditions.

R thread anchor bar or called rock bolt, soil nail, which is a kind of threaded hollow bar, bar surface with an rope thread according to ISO 10208 & 1720. It was firstly invented by MAI on 1960S to solve the low construction speed on complicated underground works, nowadays; it is very popular all around the world.

-

hollow bar self drilling anchor bolt Factory Price hollow grouting rock bolts Micropile Tunnel grouting bolting

drillcategorymodelOuter diameter (mm)suitable for geological conditionsCross all-steel drillHSR32/5151Mudstone, gravel soil, chalk soil, lime soil, calcareous clay, artificial fill, soft mudstoneHSR32/7676Cross alloy drillHSR32/5151Soft to medium hard rock, e.g. gravel with boulders, fractured rock formations, unreinforced concretemud drillHSR32/7676Clay, soft soil, sandy soil, gravel, mixed fillBall tooth all-steel drillHSR32/5151Crushed formations, soft sandstone, limestone, gravel, soft rock formationsHSR32/7676Ball tooth alloy drillHSR32/5151Soft to medium hard weathered rock formations, boulders, gravel such as mudstone, schist, volcanic rocks, etc. -

High Strength SN Tunnel Rock Bolt Self Drilling Mining Anchor Bolt

Advantages and Characteristics as below:

5. Continuous threads ensure the bars can be cut and coupled at any point, or extended.

6. Different anchor bits are available for different ground conditions.

-

-

hign strength steel bolt full thread reinforcing bars cast steel nuts rock bolt anchor rod bolt for Mine tunnel

PRODUCT PARAMETERSTypeOuter Dia(mm)Inner Dia(mm)thickness(mm)Ultimate(KN) loadYield Load(KN)Weight(Kg/m)R25N25145.52001502.3R32L3221.55.2521016002.8R32N321683602803.4R32S321683602804.1R383817/19/2210.5/9.5/8450/400/350550/500/4206.3/5.9/5.2R515129/33/3511/9/8800/660/550640/540/4509/7.7/7T76N765112.51600120015T76S764515.51900150019.7T103N1037812.52282180027.3T103S10351263460275042T30/1130119.53202603.1T30/14301482602202.8T30/1630157.52201802.7T40/164016126605257T40/20402295394305.6T52/2652261392973010T73/53735310163097012.3T73/5673568.5141478511T73/457245141630118017.8T130/6013060357940525075 -

R32 51 anchor button bits for self drilling bolt hollow anchor bar anchor rods for Rock Bolting

Self-drilling anchor bolts are applied widely, such as tunneling, quarrying, well drilling, civil engineering, dimensional stone,

demolition, and recycling. We have a strong commitment to enhancing our customer’s productivity, profitability and safety. We arecommitted to driving our sustainable development as part of our offering, researching and development and our attractiveness as anemployer. Our objective is to contribute to global sustainable development, with products and olutions that support the creation of a more sustainable world. We show respect for people, environment and the communities in which we are active. -

Mining Roof Bolts/Mining Rock Bolts/Anchor Bolts/Split bolts

SpecificationDiameter(±0.5)33mm39mm40mm42mm46mm47mmLength(±0.5)1.2m1.5m1.9m2.0m2.5m3mMining Plate(±0.5)140*140*6mm,150*150*5mm,200*200*10mmMaterialQ235,16Mn,20 MnsiAdvantage

1. The raw material is high-strength alloy strip steel; 2. The installation is the easiest; 3. No anchoring agent required; 4. The friction between the bolt and the rock mass is large; 5. It has high shear and tensile strength; 6. Equipped with high-strength pallet, the pallet is evenly stressed;ApplicationThe split sets anchor is the most basic part of the roadway support in mining. Reinforce the surrounding rock of the roadway so that the surrounding rock can Stablize. friction anchors are now used not only in mines, but also in strengthening slopes, tunnels and dams. -

R38L 1000mm to 8000mm Anchor Tool Self Drilling Anchor Bolt Threraded Bar Anchor Rods

-

-

self drilling hollow grouting rock bolts Micropile Tunnel grouting bolt mining equipment Underground Mining Tunnel Arch Support

The Self Drilling Anchor system is comprised of a hollow threaded anchor bar with a sacrificial drill bit that performs

drilling,anchoring and grouting in a single operation. Self drilling anchor system is mainly used in slope stabilization,

tunneling pre-support, foundations with micro piles etc projects.

Advantages and Characteristics as below:

1. No casings required, because anchor bars can be drilled into loose soils without needing casings to support the boreholes.

2. Fast drilling and installation, because drilling, installation and grouting are in a single operation.

3. Both rope threads and trapezoid threads are robust and ideal for rotary-percussive drilling and ensuring a high level of

bondwith the borehole gout.

4. The hollow core not only serves for flushing during drilling, but also for grouting after drilling.

5. Continuous threads ensure the bars can be cut and coupled at any point, or extended.

6. Different anchor bits are available for different ground conditions.

-

T thread self drilling rock anchor bolt T76N T76S

Full threaded steel self drilling rock bolt / Hollow anchor bar / Anchor rods

The Self Drilling Anchor system is comprised of a hollow threaded anchor bar with a sacrificial drill bit that performs

drilling,anchoring and grouting in a single operation. Self drilling anchor system is mainly used in slope stabilization,

tunneling pre-support, foundations with micro piles etc projects.

Advantages and Characteristics as below:

1. No casings required, because anchor bars can be drilled into loose soils without needing casings to support the boreholes.

2. Fast drilling and installation, because drilling, installation and grouting are in a single operation.

3. Both rope threads and trapezoid threads are robust and ideal for rotary-percussive drilling and ensuring a high level of

bondwith the borehole gout.

4. The hollow core not only serves for flushing during drilling, but also for grouting after drilling.

5. Continuous threads ensure the bars can be cut and coupled at any point, or extended.

6. Different anchor bits are available for different ground conditions.

-

Self Drilling Anchor T30 T40 T52 Self Drilling Rock Micropiles Vs Piles Steel Anchor Bolt

Self-drilling anchors are mainly used in railways, highways, tunnels, mines, water conservancy projects, slopes, dams, bridge foundations, riversides of rivers, seas and lakes, high-rise building foundations and building reinforcement projects. The pressure grouting of the bolt through the hollow rod can achieve the purpose of anchoring the broken rock mass, cutting off the groundwater and the rod body anti-corrosion, and can quickly form a supporting force together with the rock mass to control the stability of the surrounding rock mass. The main components of the self-drilling anchor are: hollow bolt body, stopper, backing plate, nut and anchor head (drill bit). Specifications and models of self-drilling anchors:diameters are 25mm, 28mm, 30mm, 32mm, 50mm, etc., and thicknesses are 3mm, 5mm, 6mm, etc. The length of self-drilling anchors can be customized according to customer requirements.

Hello, come to consult our products !