Blast Furnace Drill Rod Factory Factory – Blast furnace drill rod – LYNE

Blast Furnace Drill Rod Factory Factory – Blast furnace drill rod – LYNE Detail:

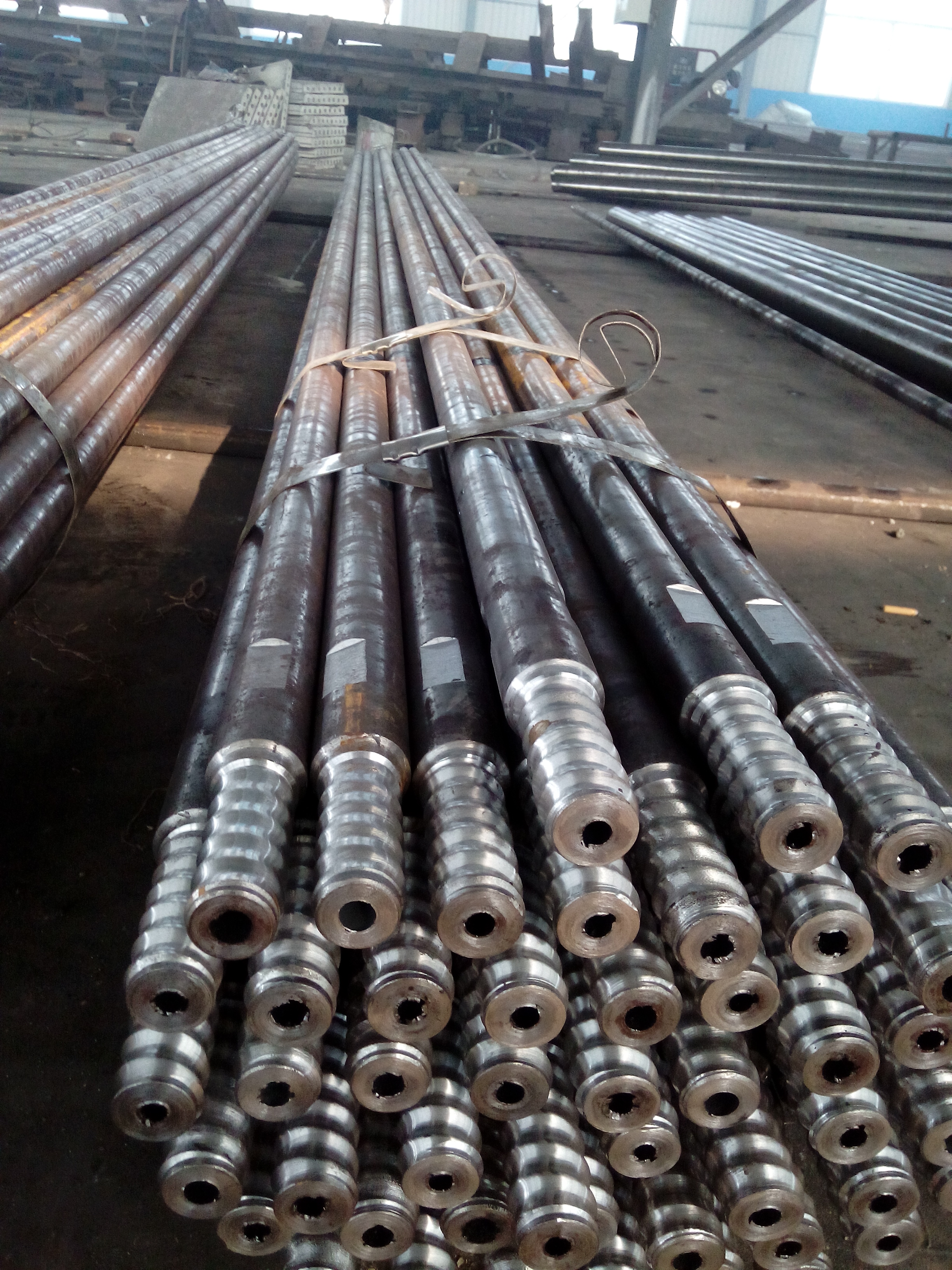

Single-Lug (Double-Lug) Threaded Drill Rod

|

Description |

Length |

Diameter |

Part No. |

||

|

mm |

in |

mm |

in |

||

|

1830 | 6′ | 32 | 1 1/4” | MT32-18 H25L |

| 2435 | 8′ | 32 | 1 1/4” | MT32-24 H25L | |

| 3050 | 10′ | 32 | 1 1/4” | MT32-30 H25L | |

| 3660 | 12′ | 32 | 1 1/4” | MT32-36 H25L | |

| 3830 | 12’6” | 32 | 1 1/4” | MT32-38 H25L | |

| 4300 | 14’1” | 32 | 1 1/4” | MT32-43 H25L | |

| 1830 | 6′ | 38 | 1 1/2” | MT38-18 D30L | |

| 2435 | 8′ | 38 | 1 1/2” | MT38-24 D30L | |

| 3050 | 10′ | 38 | 1 1/2” | MT38-30 D30L | |

| 3660 | 12′ | 38 | 1 1/2” | MT38-36D30L | |

| 3830 | 12’6” | 38 | 1 1/2” | MT38-38D30L | |

| 4300 | 14’1” | 38 | 1 1/2” | MT38-43 D30L | |

Single-Lug(Double-Lug) Welding Drill Rod

|

Description |

Length |

Diameter |

Part No. |

||

|

mm |

in |

mm |

in |

||

|

3500 | 11’6” | 32 | 1 1/4” | MW32-35L |

| 4270 | 14′ | 32 | 1 1/4” | MW32-35L | |

| 4420 | 14’6” | 32 | 1 1/4” | MW32-35L | |

| 5000 | 16’4” | 32 | 1 1/4” | MW32-35L | |

| 5400 | 17’7” | 32 | 1 1/4” | MW32-35L | |

| 6000 | 19’8” | 32 | 1 1/4” | MW32-35L | |

| 3500 | 11’6” | 38 | 1 1/2” | MW38-35L | |

| 4270 | 14′ | 38 | 1 1/2” | MW38-35L | |

| 4420 | 14’6” | 38 | 1 1/2” | MW38-35L | |

| 5000 | 16’4” | 38 | 1 1/2” | MW38-35L | |

| 5400 | 17’7” | 38 | 1 1/2” | MW38-35L | |

| 6000 | 19’8′ | 38 | 1 1/2” | MW38-35L | |

Extension Drill Rod

|

Description |

Length |

Diameter |

Part No. |

||

|

mm |

in |

mm |

in |

||

|

1830 |

6′ |

32 |

1 1/4” |

ME32-18R32/H25 |

|

2435 |

8′ |

32 |

1 1/4” |

ME32-18R32/H25 |

|

|

3050 |

10′

|

32 |

1 1/4” |

ME32-18R32/H25 |

|

|

3660 |

12′ |

32 |

1 1/4” |

ME32-18R32/H25 |

|

|

3830 |

12’6” |

32 |

1 1/4” |

ME32-18R32/H25 |

|

|

4300 |

14’1” |

32 |

1 1/4” |

ME32-18R32/H25 |

|

|

1830 |

6′ |

38 |

1 1/2” |

ME38-18R38/R38 (ME38-18R38 / D30) |

|

|

2435 |

8′ |

38 |

1 1/2” |

ME38-18R38/R38 (ME38-18R38 / D30) |

|

|

3050 |

10′ |

38 |

1 1/2” |

ME38-18R38/R38 (ME38-18R38 / D30) |

|

|

3660 |

12′ |

38 |

1 1/2” |

ME38-18R38/R38 (ME38-18R38 / D30) |

|

|

3830 |

12’6” |

38 |

1 1/2” |

ME38-18R38/R38 (ME38-18R38 / D30) |

|

|

4300 |

14’1” |

38 |

1 1/2” |

ME38-18R38/R38 (ME38-18R38 / D30) |

|

Semi-finished Materials

|

Description |

Length |

Part No. |

|

|

mm |

in |

||

|

32 |

1 1/4” |

Hollow Drill Steel |

|

38 |

1 1/2” |

||

|

32 |

1 1/4” |

Seamless Steel Pipe |

|

38 |

1 1/2” | ||

Coupling Sleeve

|

Description |

Length |

Diameter |

Thread |

Part No. |

||

|

mm |

in |

mm |

in |

|||

|

150 | 5 29/32” | 44 | 1 47/64” | R32 | MC4415-R32 |

| 170 | 6 3/4” | 55 | 2 5/32” | R35 | MC5517-R35 | |

| 170 | 6 3/4” | 55 | 2 5/32” | R38 | MC5517-R38 | |

Pneumatic Break Steel

|

Point |

Shank Size |

Length |

Part No. |

Weight |

||

|

mm |

in |

mm |

in |

Kg |

||

|

22×82.5 22×108 |

7/8” x 31/4” 7/8” x 41/4” |

355 |

14” |

MP2201-355 |

1.55 |

|

457 |

18” |

MP2201-457 |

1.9 |

|||

|

609 |

24” |

MP2201-609 |

2.41 |

|||

|

914 |

36” |

MP2201-914 |

3.43 |

|||

|

25×108 |

1” x 41/4” |

355 |

14” |

MP2501-355 |

1.99 |

|

|

457 |

18” |

MP2501-457 |

2.42 |

|||

|

609 |

24” |

MP2501-609 |

3.08 |

|||

|

914 |

36” |

MP2501-914 |

4.47 |

|||

|

1219 |

48” |

MP2501-1219 |

5.7 |

|||

|

1524 |

60” |

MP2501-1524 |

7.01 |

|||

|

1828 |

72” |

MP2501-1828 |

8.32 |

|||

| 28×152 | 11/8” x 6” |

355 |

14” |

MP2801-355 |

2.72 |

|

|

457 |

18” |

MP2801-457 |

3.24 |

|||

|

609 |

24” |

MP2801-609 |

4.05 |

|||

|

914 |

36” |

MP2801-914 |

5.68 |

|||

|

1219 |

48” |

MP2801-1219 |

7.3 |

|||

|

1524 |

60” |

MP2801-1524 |

8.93 |

|||

|

1828 |

72” |

MP2801-1828 |

10.55 |

|||

|

32×152 (32×160) |

11/4” x 6” 11/4” x 61/3” |

355 |

14” |

MP3201-355 |

3.93 |

|

|

457 |

18” |

MP3201-457 |

4.08 |

|||

|

609 |

24” |

MP3201-609 |

6.43 |

|||

|

914 |

36” |

MP3201-914 |

7.08 |

|||

|

1219 |

48” |

MP3201-1219 |

9.1 |

|||

|

1524 |

60” |

MP3201-1524 |

11.11 |

|||

|

1828 |

72” |

MP3201-1828 |

13.12

|

|||

|

Chisel |

Shank Size |

Length |

Part No. |

Weight |

||

|

mm |

in |

mm |

in |

Kg |

||

|

22×82 22×108 |

7/8” x 31/4” 7/8” x 41/4” |

355 |

14” |

MP2202-355 |

1.55 |

|

457 |

18” |

MP2202-457 |

1.9 |

|||

|

609 |

24” |

MP2202-609 |

2.41 |

|||

|

914 |

36” |

MP2202-914 |

3.43 |

|||

|

25×108 |

1” x 41/4” |

355 |

14” |

MP2502-355 |

1.99 |

|

|

457 |

18” |

MP2502-457 |

2.42 |

|||

|

609 |

24” |

MP2502-609 |

3.08 |

|||

|

914 |

36” |

MP2502-914 |

4.4 |

|||

|

1219 |

48” |

MP2502-1219 |

5.7 |

|||

|

1524 |

60” |

MP2502-1524 |

7.01 |

|||

|

1828 |

72” |

MP2502-1828 |

8.32 |

|||

|

28×152 28×160 |

11/8” x 6”11/8” x 61/3” |

355 |

14” |

MP2802-355 |

2.72 |

|

|

457 |

18” |

MP2802-457 |

3.24 |

|||

|

609 |

24” |

MP2802-609 |

4.06 |

|||

|

914 |

36” |

MP2802-914 |

5.68 |

|||

|

1219 |

48” |

MP2802-1219 |

7.3 |

|||

|

1524 |

60” |

MP2802-1524 |

8.93 |

|||

|

1828 |

72” |

MP2802-1828 |

10.55 |

|||

|

32×152 (32×160) |

11/4” x 6” 11/4” x 61/3” |

355 |

14” |

MP3202-355 |

3.39 |

|

|

457 |

18” |

MP3202-457 |

4.08 |

|||

|

609 |

24” |

MP3202-609 |

6.43 |

|||

|

914 |

36” |

MP3202-914 |

7.08 |

|||

|

1219 |

48” |

MP3202-1219 |

9.1 |

|||

|

1524 |

60” |

MP3202-1524 |

11.11 |

|||

|

1828 |

72” |

MP3202-1828 |

13.12 |

|||

Welding Button Bit Part No. Rules

M WB 38 20 -7 A

|

M |

||

|

WB |

Welding Button Bit |

|

|

38 |

Diameter |

38mm-70mm |

|

20 |

d |

16.5mm-21mm |

|

7 |

Carbide Number |

6-9 |

|

A |

A |

L=18 |

|

B |

L=10 | |

Taphole Drill Rod Part No. Rules

M T 32 -18 R32/H25L

|

M |

MAXDRILL |

|

|

T |

T |

Threaded Drill Rod |

|

W |

Welding Drill Rod |

|

|

E |

Extension Drill Rod |

|

|

C |

Coupling Sleeve |

|

|

32 |

Diameter |

|

|

18 |

Length |

1830mm-4300mm |

|

R32 |

Thread |

|

|

H25 |

||

|

L |

Lug |

|

Pneumatic Break Steel Part No.

Rules

M P 22 01 -355

|

M |

MAXDRILL |

|

|

P |

Pneumatic Break Steel |

|

|

22 |

Shank Size |

Hex.22mm, Hex.25mm, Hex.28mm, Hex.32mm, |

|

01 |

01 |

Head type point |

|

02 |

Head type chisel |

|

|

355 |

Length |

355mm-1828mm |

The drill pipe is a threaded steel pipe at the tail that connects the rig surface equipment to the drilling equipment or the bottom hole device located at the bottom of the drilling rig. The purpose of the drill pipe is to transport the drill mud to the drill bit and, together with the drill bit, to raise, lower or rotate the bottom hole device. Drill pipes can withstand large internal and external pressures, twists, bends and vibrations. Drill pipes can be used multiple times during the extraction and extraction of oil and gas. Drill pipe is divided into square drill pipe, drill pipe and aggravated drill pipe three categories. The connection order is square drill pipe, drill pipe and aggravated drill pipe.

The wall thickness of blast furnace drill pipe is divided into 8mm and 12mm. The price is calculated per meter, and the length can be customized.

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for Blast Furnace Drill Rod Factory Factory – Blast furnace drill rod – LYNE , The product will supply to all over the world, such as: Algeria, Cancun, Lesotho, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!