Atlas Copco Rock Drilling Machine Suppliers – Bench and long-hole drilling ST68 (2 3/4″) – LYNE

Atlas Copco Rock Drilling Machine Suppliers – Bench and long-hole drilling ST68 (2 3/4″) – LYNE Detail:

Bench and long-hole drilling ST68 (2 3/4″)

R25 (1”)

R28 (1 1/8”)

R32 (1 1/4”)

R/T38 (1 1/2”)

T45 (1 3/4”)

T51 (2”)

T60 (2 3/8”)

Drill bit R/T38

Extension rod T38 – Hex. 32 mm – T38

Extension rod T38 – Round 38 mm – T38 (Speedrod)

Extension rod R38 – Round 38 mm – R38

Extension rod T38 – Round 38 mm – T38

Extenstion rod T38 – Round 38 mm – T38 (with double thread)

Guide rod T38 – Round 45 mm – T38 (Speedrod)

Guide tube T38

Coupling R/T 38

| Bits |

Diameter |

Buttons,mm |

Angle |

Flushing hole |

Weight approx kg |

Part No. |

||||||

|

mm |

in |

Front No Size |

Gauge No Size |

Type |

Front |

Gauge |

||||||

| Button bit | ||||||||||||

|

102 |

4” |

8×12 |

10×12 |

|

35º |

4 |

- |

5.2 |

1432-102ST68-812/1012-45-51 |

||

|

115 |

4 1/2” |

8×14 |

10×14 |

|

35º |

4 |

- |

5.9 |

1432-115ST68-814/1014-45-51 |

|||

| Button bit | ||||||||||

|

102 |

4” |

6×13 |

8×14 |

|

35º |

2 |

- |

5.5 |

1431-102ST68-613/814-45-41 |

| Button bit, Retrac | ||||||||||

|

102 |

4” |

8×12 |

10×12 |

|

35º |

4 |

- |

6.2 |

1632-102ST68-812/1012-45-51 |

|

115 |

4 1/2” |

8×14 |

10×14 |

|

35º |

4 |

- |

8.4 |

1632-115ST68-814/1014-45-51 |

|

|

102 |

4” |

7×12 |

9×12 |

35º |

3 |

- |

6.2 |

1531-102ST68-712/912-45-41 |

||

|

115 |

4 1/2” |

7×13 |

9×13 |

35º |

3 |

- |

8.4 |

1531-115ST68-713/913-45-41 |

||

| Collaring bit, ST68 | ||||||||||

|

152 |

6” |

8×16 |

9×16 |

|

35º |

3 |

- |

9.8 |

1431-152ST68-816/916-45-41 |

| Reaming bit, ST68 | ||||||||||

|

152 |

6” |

6×14 |

8×14 |

|

35º |

4 |

- |

14.0 |

1441-152ST68-614/814-45-41 |

| Tubes |

Length |

Diameter |

Weight approx kg |

Part No. |

||

|

mm |

ft/in |

mm |

inch |

|||

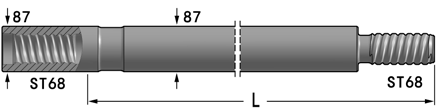

| Drill tube, ST68-Round87-ST68 | ||||||

|

1525 |

5' |

87 |

3 1/2′ |

40.0 |

24G87-ST68/87-1525-23 |

|

1830 |

6' |

87 |

3 1/2′ |

47.0 |

24G87-ST68/87-1830-23 |

|

Carburization is a process used to harden the entire rod surface both internally and externally to strengthen and extend the life of the rod.

High Frequency Induction is a process where only the thread ends of the rod are hardened to lengthen thread life.

Our comprehensive range of bench and production rock drilling tools includes everything from 1” rope thread equipment all the way up to T60 thread equipment, Many customers say that our rods, tubes and button bits are the best on the market today. Let’s just say they will improve productivity considerably.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Atlas Copco Rock Drilling Machine Suppliers – Bench and long-hole drilling ST68 (2 3/4″) – LYNE , The product will supply to all over the world, such as: Eindhoven, Germany, Eindhoven, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!